How Geosynthetics are Improving Construction Projects

Geosynthetics are rapidly becoming the go-to solution for improving a wide range of construction projects. Their technology has revolutionized the industry by providing the ability to create high-strength, durable, and cost savings solutions to a wide range of construction challenges.

In this blog, we will discuss the types of geosynthetics and how they can improve construction projects.

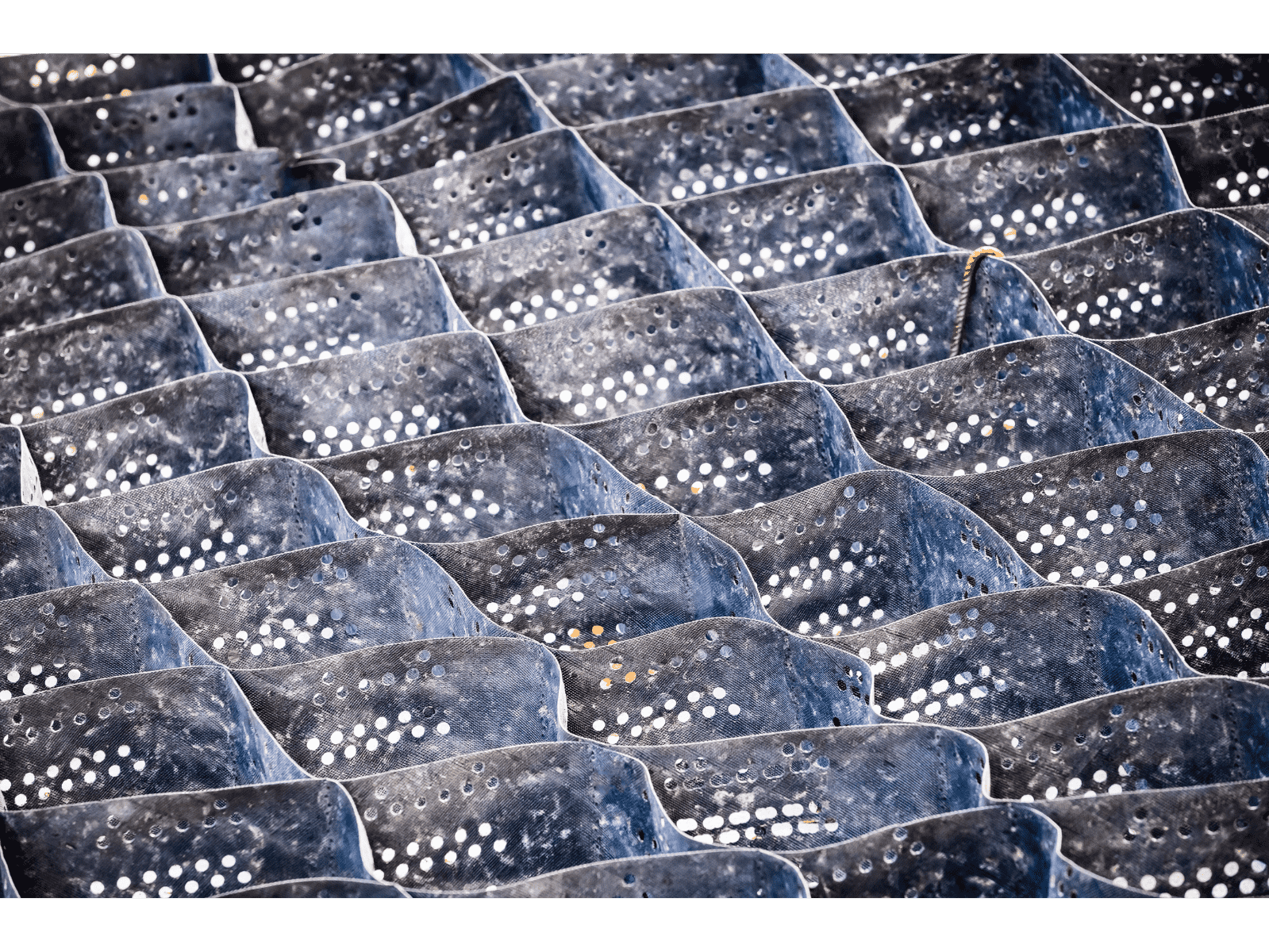

Types of Geosynthetics

Flexible geosynthetic material is common. Flexible forms include geotextiles and geomembranes. Geosynthetic clay liners use natural materials like clay and bentonite to create a barrier that prevents contamination from chemicals and other materials. High density polyethylene is a popular choice for geosynthetics due to its strength and durability.

Soil Stabilization

One benefit of geosynthetics is their ability to improve soil stabilization. Geosynthetics can be used to reinforce soil for a variety of construction projects, including roadway construction and embankment reconstruction. Reinforced soils provide an excellent foundation for construction projects, which increase their durability and prevent soil loss. The use of geosynthetics as a building material has allowed engineers to build buildings where they did not think it was possible before, thanks to the increased stability of the soil.

Drainage Systems

Another critical application of geosynthetics in construction is in drainage systems. Geosynthetic materials such as geotextiles and geocomposites are used to create drainage systems that provide protection to environmental surroundings. These systems work by filtering water through the geosynthetic, which removes impurities, thus providing clean drainage. The use of geosynthetics in drainage systems has been shown to help with erosion control, enhance water conservation, and improve water quality.

Landfills

Furthermore, the use of geosynthetics has also enabled the construction of landfill sites with minimum environmental impact. Geosynthetics can line landfills, regulating the seepage of toxins and other pollutants off-site. Once the geosynthetic products are established in the landfill, leachate flows down to be collected and transported for treatment. As a result, geosynthetics help reduce the degradation of the environment and minimize public health risks associated with landfills.

Asphalt Construction

Geosynthetics also play a big role in asphalt construction. The addition of geosynthetics in asphalt mixtures fosters enhanced durability, safety, and sustainability. Polypropylene fibers, for example, provide a solution to the significant challenges with asphalt shoving by decreasing the maximum shear stress in the layer bound. In addition, geosynthetics minimize cracking by subduing the stress buildup related to temperature alterations and stop crack propagation. By offering resistance from ultraviolet (UV) radiation, geosynthetics also reduce surface raveling for a more extended lifespan of the surfacing.

In conclusion, geosynthetics are making significant contributions to the construction industry and help with cost savings. Different geosynthetics can be used in a variety of projects. They have revolutionized the industry by improving soil stabilization, providing efficient drainage systems, minimizing environmental impact in landfill sites, and strengthening asphalt construction. If you are planning on beginning a construction project, consider using geosynthetics. Contact ECS Products today to learn more about how you can incorporate geosynthetics in your construction project.